RHEINZINK angled standing seam

The reliable angled standing seam roof system made from titanium zinc

Benefits of angled standing seams made from RHEINZINK

- Long-lasting roof system with striking seams for roof inclinations from 25°

- System approved by building inspection authorities for improved reliability

- Extensive range of semi-finished products and matching roof drainage products from a single source

Angled standing seams by RHEINZINK: A long-established solution

Many system solutions by RHEINZINK are based on well-established procedures that were already employed over 100 years ago. Some features of these procedures are still used unchanged today, even though RHEINZINK now offers numerous further developments thanks to our innovative spirit and practical approach. The angled standing seam is a good example of this and has been used since the beginning of the 20th century. It is particularly advantageous to use angled standing seams as a roofing system on roof inclinations of more than 25° or 35° in regions with heavy snowfall. Using the angled standing seam system allows planners and architects to capitalise on great freedom of design. The visually striking structure is characteristic of angled standing seam systems.

RHEINZINK angled standing seam programme

Features of the RHEINZINK angled standing seam system

- Strikingly dynamic structure for small and large surfaces

- Individual adaptation options for tapered, concave and convex rounded surfaces

- The individual elements can be installed vertically, diagonally or horizontally and allow interesting and aesthetically pleasing roof surfaces to be planned

- The matching system technology facilitates rapid assembly

The RHEINZINK programme contains system solutions for a wide range of requirements. The angled standing seam system is an excellent choice for classic roofs with a steep inclination of at least 25°. Planners and architects benefit from easy handling where angled standing seam systems are used for refurbishment projects. Large roof surfaces can be covered economically while adequately taking individual elements of a building into account. It can be almost effortlessly combined with parapets, fascias and attics.

Where angled standing seam roofing is planned, planners or architects often face the challenge of taking adequate care to consider numerous different elements. RHEINZINK also supplies an extensive range of accessories to match our angled standing seam system for roof surfaces. Snow guard systems, safety devices, step systems, seam seals and a simple fastening system complete our programme.

Angled standing seam planning and application

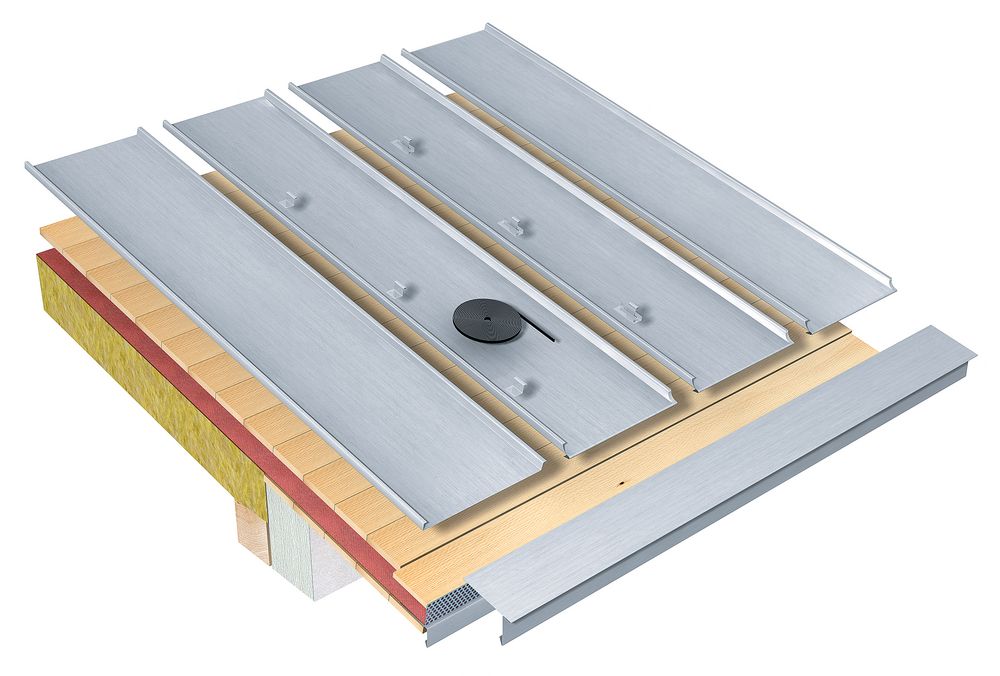

System description

- Roofing from 25° roof inclination

- In snowy regions from 35° roof inclination

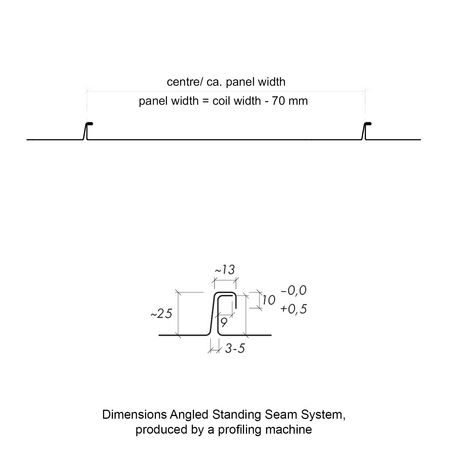

Angled standing seam systems are used in the roof and facade sector and for cladding small surfaces such as fascias and upstands etc. They are ideal for visually separating roof and facade surfaces thanks to their height of approx. 25 mm and a seam width of approx. 12 mm. They are distinguished by particularly low material stresses. In contrast to double standing seams, only one side is closed using a machine or by hand. The angled standing seam is produced using roll formers (length ≤ 16 m) or bending brakes (length ≤ 4 m). Tapered areas and concave and convex rounded surfaces can be covered and clad using these elements.

Dimensions and metal thickness

- Standard panel width approx. 500 mm (coil width 575 mm)

- Common panel widths 430 mm to 500 mm

- Metal thicknesses 0.7 mm/0.8 mm

- Normal panel length up to 10 m

- In special cases up to 16 m

- Deliverable lengths max. 7 m

The international standard size for roofs in angled standing seam systems is a panel width of approx. 530 mm (coil width 600 mm) and a metal thickness of 0.7 mm. We recommend limiting the panel width to 430 mm and the metal thickness to 0.8 mm for mono pitch roofs with overhangs based on practical construction experience. This measure prevents noises that can occur in strong winds due to the natural curvature of the panels.

In general, the normal maximum panel length is 10 m. In special cases, panels up to 16 m in length can also be installed. However, the roof inclination then remains limited to max. 30°. In this case, panel attachments and connection details must be adapted to the increased length variation.

If the max. possible panel length is insufficient, individual lengths can be connected using cross seams.

Customised forms

- Convex and concave rounded panels

- Tapered panels

The minimum radius for convex rounded, standing seam panels is 0.6 m. Starting from a radius of 12 m, panels can be installed without first pre-rounding them. If the radii are smaller, the panels must be edged by hand and stretched using manual forming pliers or a Biegeboy bending machine. For concave rounded surfaces, the seam edge must be compressed, which is more technically difficult than stretching. The minimum radius for concave rounded, standing seam panels is, therefore, 2.5 m. Pre-rounded panels cannot be installed above a radius of 25 m.

Tapered panels are used to construct roofs over round floor plans or for special details in roof valleys. For reasons of production feasibility, the panel width of tapered panels must be at least 100 mm and max. 730 mm, depending on wind loads. The max. panel width of 530 mm must be adhered to for mono pitch roofs.

RHEINZINK offers the highest product quality

We use high-quality raw materials and high-tech production methods to guarantee consistently excellent product quality at all times.

Of course, using an angled standing seam system is an investment decision that takes careful consideration. The economical assembly using CLIPFIX products and the durability of angled standing seam systems will help you to make this decision. Compared to many cheaper products, standing seam systems have an impressive service life that will last multiple generations and are maintenance-free. Once installed, roofs and roof systems withstand decades of wind and weather and reliably protect a building structure.

All important information concerning our angled standing seam solution and interesting design examples can be downloaded from our website at any time. The RHEINZINK team would also be glad to help you with questions of any kind. You can also personally take a look at our products by visiting one of our specialist dealers or professional specialists at their premises. You can easily find your nearest dealer or professional specialist using our online dealer or specialist locator. We look forward to hearing from you and are sure that we will be able to impress you with our extraordinary products.

Downloads

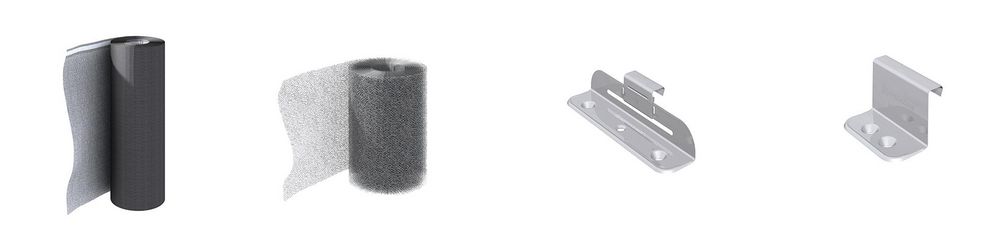

- Delivery ProgrammeAIR-Z and VAPOZINCProduct Information - structured mat and the structured underlay

- Declarations of PerformanceDeclaration of Performance Dowel-type fasteners CLIPFIX stainless steel with EN 14592

- Declarations of PerformanceDeclaration of Performance Dowel-type fasteners CLIPFIX steel with EN 14592

- Declarations of PerformanceDeclaration of Performance Standing seam panel with EN 14783

- Declarations of PerformanceDeclaration of Performance Structured underlay VAPOZINC with EN 13252

- Planning DocumentsDesign Recommendations for Roof Coverings

- BrochuresRoofingSystem Overview

- Planning DocumentsStanding Seam TechnologyInstallation Guideline